27

2025

-

03

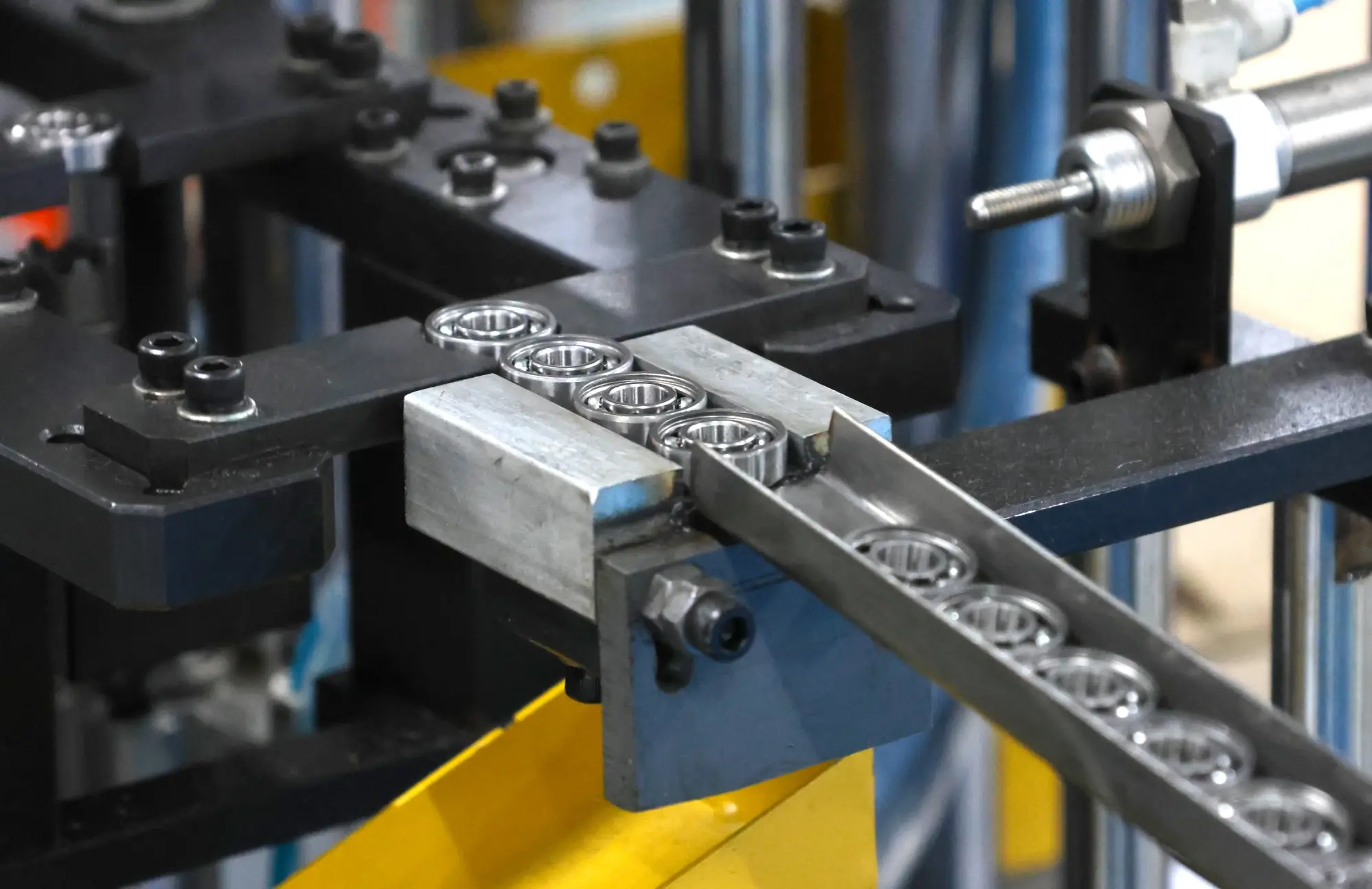

Bearing production to improve the quality of the elements

Author:

Bearings are the most important parts of machinery, the use of quality is the first choice of bearings, in the production process to improve the quality of bearings, today to tell you mainly from the five elements in the production to improve the quality of bearing requirements.

1, the motor assembly site should be kept clean, bearing coated with grease, the site is not allowed to fly dust. The parts matched with the bearing must go through strict inspection before assembly, and any small link can not be ignored. For example, the shaft shoulder at the match of the shaft and the bearing, if it is cleared without rounded corners, it is easy to produce stress concentration during operation and twist the shaft here; If the rounded Angle is too large, or the grinding process is not in place, the interference amount of the inner ring will be out of whack when the bearing is installed, or the bearing can not be in place, which is the root of premature bearing damage.

2, the dynamic balance quality is a crucial factor affecting the bearing life. The larger the motor, the higher the speed, the higher the quality requirements for dynamic balance.

3, bearing related parts - frame, end cover, rotor, bearing inner, outer cover of the coaxial degree is better, and ensure that in the operation of the motor not due to the deformation of the parts are destroyed. Large parts, such as frame, end cover, etc., must be aging treatment.

4, the processing accuracy of bearing related parts should be improved. Because the processing accuracy of the bearing itself is very high, and when the bearing is matched with the relevant parts, the very small interference amount will cause the damage of the bearing. Practice has proved that the tolerance zone can be controlled in the range of 0, 02mm by using CNC machine tool with "fixed size tool" machining bearing chamber. The roughness of the match with the inner and outer ring of the bearing should also be improved as far as possible, otherwise, after multiple disassembly and grinding off the "knife peak" of the gold processing, the match tolerance of the original design will also change.

5, the grease should be appropriate, otherwise the bearing should heat up. If the ambient temperature is higher than 40 ° C, choose a grease with a higher penetration degree. On the contrary, low penetration or special greases should be used.

Bearing in the use of failure is inevitable, if the quality of the bearing is improved, it depends on the use of bearings, we can also choose bearings through the above five aspects to understand, can refer to the quality of the bearing in the end.

RELATED NEWS